CERTIFICATION

Tightwinder

Field Test Results

Load Restraint Assessment

Physical Stance & Pretension Measurements

Fleet Drivers’ Manual Input Effort Results

For TransKing Tightwinder &

The Glen Cameron Group

October 2011 & Update March 2017

Introduction

The purpose of the 2011 Tightwinder Load Restraint Assessment review and 2017 update was to measure how much manual input effort drivers and operators apply to the restraint tensioning handles when using the geared Tight-winder geared winch. Typical levels of pretension or clamping force attained was matched with the manual input effort comparisons from different peoples’ input. Both Trans-King and the Glen Cameron group share concerns about the injury risks amongst transport operations involved the possible over-exertion of the tensioning handle/binder bars whilst restraining loads.

Other objectives were to offer comment in respect to any of the present equipment or methods that may be considered to achieve a reduced risk from the manual handling input aspect.

Scope of Manual Input Measuring Task

2. To video some typical levels of manual input achieved by several different people. In the process to measure how much down-force or lashing pretension is being achieved with the range of different manual input effort using short and long handles.

3. To measure and confirm that pretension requirements for Load Restraint is achieved when applying manual input force using one hand and a safe stance manner.

Physical Input Assessment Comparisons Summary – 2017 Update

1. Present Tight-Winder under-floor equipment and tensioning procedures used are producing excellent pre-tension levels that are approaching double the tension levels necessary for adequate load restraint tension levels for the load weights carried. The high manual input and injury risk is of ongoing concern when drivers’ ‘over-tension’ such a geared winch.

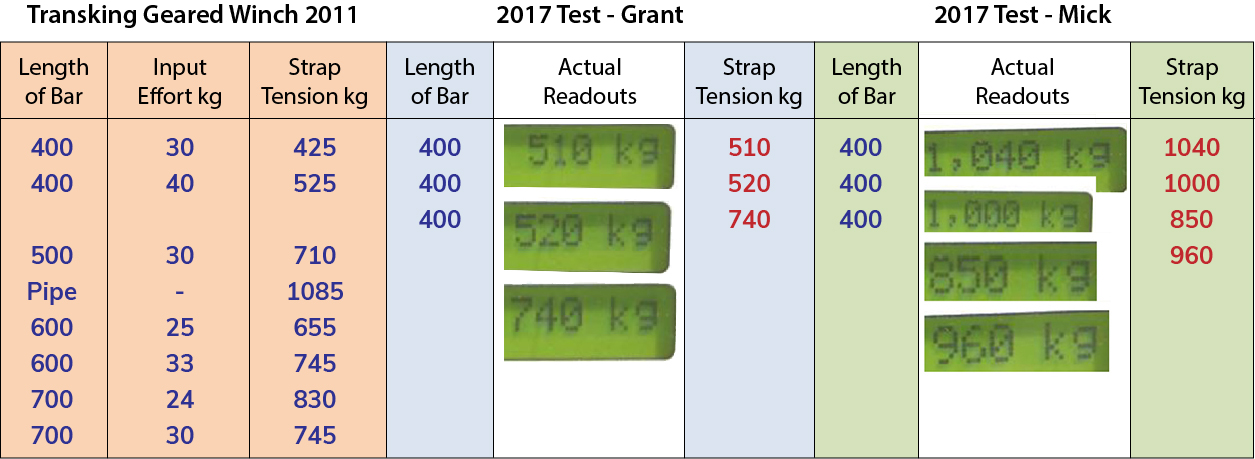

2. The key objective of these tests were to measure and confirm the regular operator manual input force as well as the tension levels attained using a Tight-Winder load restraint under-floor sliding winch and a 21 tooth regular winch as fitted to the rigid truck for comparison. Using this procedure we were able to identify a level of potentially high risk manual effort and ‘over tensioning’. (see 2017 summary tables below)

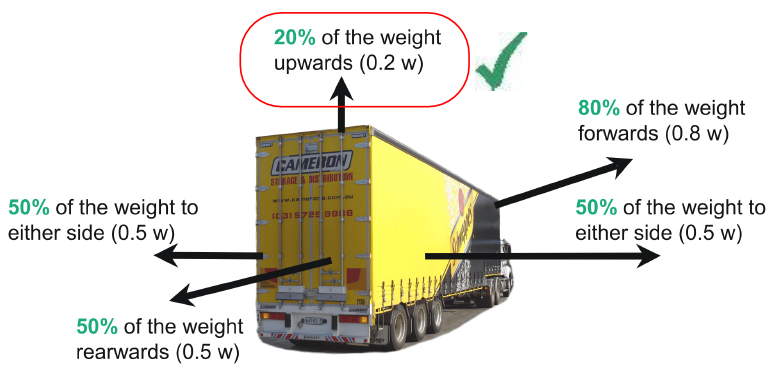

3. The necessary required load restraint minimum 20% down force/clamping of the load weight is being exceeded by most regular drivers’ who have their personal concerns that high levels of manual input (& injury risk) are ‘always required to ensure no load shift’ of the loads.

Indicative Average Test Results Summary:

The Challenge:

2. Confirmation that the regular tension levels attained are excellent. (based on many measures)

3. The Trans-King under floor geared winch plus a regular handle length of 400mm using one hand for manual input is considered a low physical risk in applying adequate strap tension.

4. Over tensioning as high as 50% of rated lashing capacity (LC) exceed manufacturers’ design Std for 50mm webbing strap & greatly increases strap and tension handle socket wear?

5. To offer some video footage among drivers’ to try to encourage and assure them that current high levels of winch tensioning physical input effort should be reduced a little? Body weight does not show up as a critical input or pre-tension factor.

The Findings

Adequate lashing input can be achieved using less manual input than many drivers’ apply. 500kg of lashing pre-tension for a 20% down-force meets a 2500 kg of load weight restraint requirement.

The recommended 3 point stance is feet apart, 2 Hands, gloves & standing as below

Standard 400mm TransKing Handle

Driver Input x 1 hand:

Pre-Tension = 425kg

Input = 30kg

2017 – Driver ‘Pre-Tensions’

See above table: Grant:

510kgs / 520kgs / 740kgs

Standard 400mm TransKing Handle

Driver Input x 1 hand:

Pre-Tension = 525kg

Input = 40kg

2017 – Driver ‘Pre-Tensions’

See above table: Mick:

1040kgs / 1000kgs / 850kgs / 960kgs

Notes

The above shots show the hand grip position set as per the ‘standard Tightwinder’ bar length of 400mm.

The ‘declared’ input effort was stated to be ‘reasonably firm’ producing sufficient lashing pre-tension for load restraint to hold 2500kg of load. A typical load of pallets 20 pallets high x say 50kgs each gives a load section weight of 2000kg – load restraint tension required is 20%. This is 400kgs of strap tension. Every driver met or exceeded this required strap ‘pre-tension’ is the tests, using the Transking 2 to 1 ratio geared winch requires less driver input effort than other under-floor winches.