WHEN SAFETY MATTERS… IT ALWAYS DOES!

Safety is an integral part of the transport industry. If companies are not taking all possible steps to minimise and mitigate risks, they are leaving themselves open to workplace injuries and potential legal actions.

Transking’s philosophy is to develop innovative products to improve the safety throughout the transport industry. Transking’s innovative products are designed to reduce risks to the drivers and operators, at the same time, improving productivity.

How and why Cowra Frieght are using the Transking Tightwinder

A Cowra-based operator has had enough of workplace injuries caused by the use of traditional load binders and is moving to retrofit his entire fleet of semi-trailers and rigid vehicles with a safer and more effective alternative.

“Our problem – it’s an industry-wide problem – is that drivers get injured when trying to put extreme pressure on the old conventional load binders using a bar,” said the owner of Cowra Freightlines, Phil Beer.

Conclusion to Managing injury risks when securing loads on trucks paper

Peter Thorning and Grant Phillips Workplace Health and Safety Queensland

The risks of using dogs and cheater bars are known in the transport industry. Incidents occur frequently and some cause serious injury. Information about the risks and ways to control those risks are available from all work health and safety regulators in Australia. Other suitable ways to secure loads and equipment, which eliminate or minimise the risk from load tensioners, are widely available and at a cost which is not grossly disproportionate to the risk reduction provided. It is notable that the Load Restraint Guide website states (National Transport Commission 2012):

“After advice from Occupational Health and Safety agencies, the NTC would like to recommend that “chain and dogs” are not used for safety reasons. Following work by the Load Restraint Working Group, it has realised that fixed or pivoting lever dogs, (with or without an extension or “cheater” bar) can cause serious injury to the operator when applying or releasing the chain.”

It would be difficult for a PCBU, who uses or allows the use of dogs and cheater bars for work associated with their business, to justify that they are fulfilling their duty to eliminate or minimise risks to health and safety, so far as reasonably practicable.

Control of risks from the task of securing loads on trucks can be achieved by using safer equipment, providing appropriate information, training, instruction or supervision and effectively consulting with workers.

Are you taking precautions to ensure this doesn’t happen to you?

With Transking’s innovative Tightwinder you could greatly reduce the risk of being badly injured. It can decrease your OH&S issues and create a safer working environment for your drivers.

Quickstrap and other Transking Safety Innovations

Strains, sprains, and Body stressing average about 40% of serious injuries in our workers compensation systems.

Quickstrap and other products employed by the transport and logistics industry help reduce the severity of workplace injuries because the tasks are safer.

Financially the cost of workers compensation premiums is better controlled because people that are injured return to work earlier often within 4 weeks, which reduces the burden on health services, families, and the economy.

The real value for employers is the ability to be more competitive through reduced lost time injuries and providing a safer working environment for an industry that is critical for the distribution of goods and services across Australia.

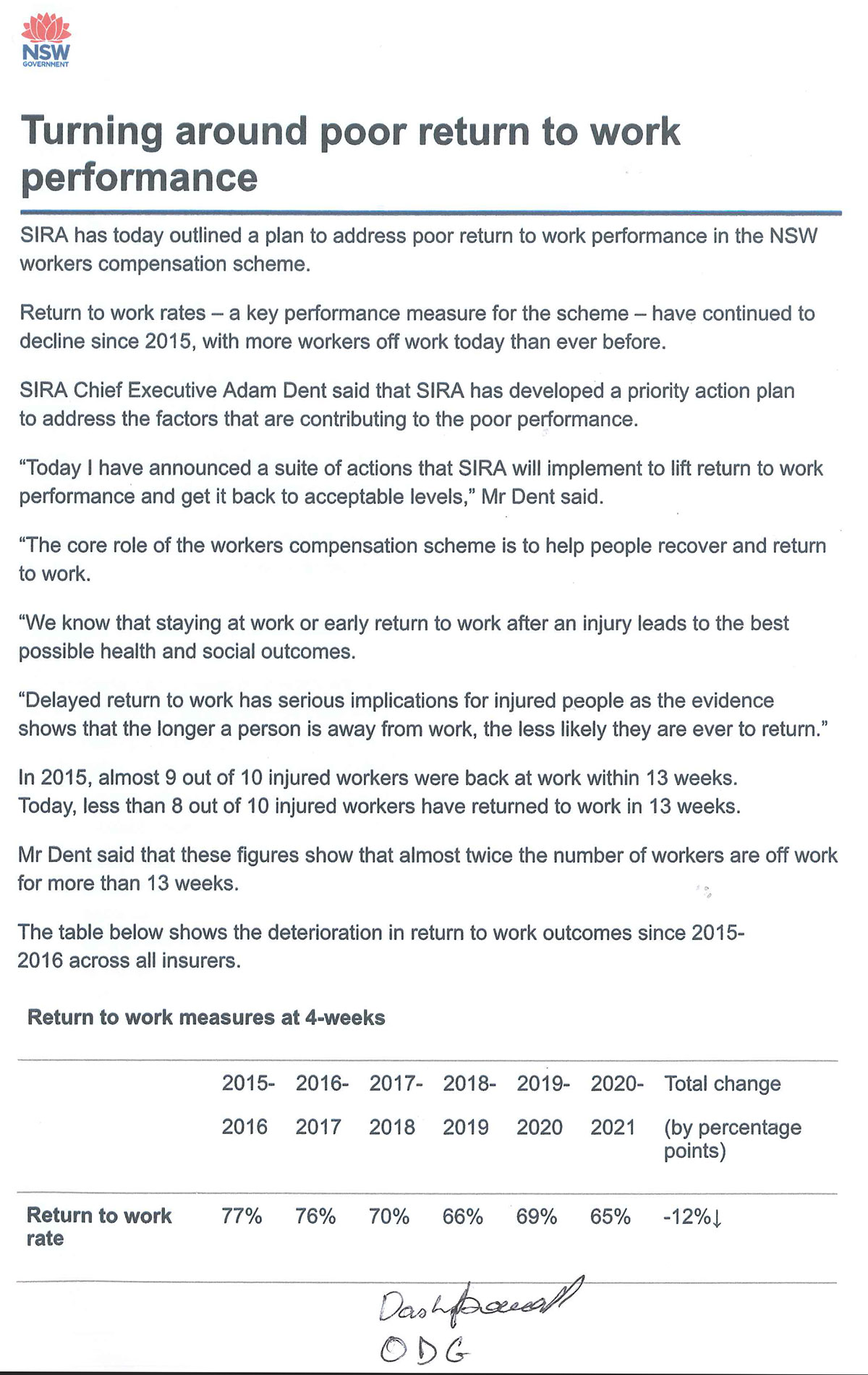

In NSW this measure has deteriorated to 66% over 5 years.

WorkSafe have a performance measure that monitors the % of injured workers that return to work within 4 weeks.

Employers using equipment like this are achieving over 80% and in some cases 90% return to work rates which is good for the injured workers, their families, and the workers compensation system in general.